塑料壳凹模加工的数控编程及螺旋压板机构的设计(CAD,UG三维建模)

塑料壳凹模加工的数控编程及螺旋压板机构的设计(CAD,UG三维建模)(任务书,外文翻译,设计说明书17500字,CAD图纸6张,UG三维,NC数控程序,答辩PPT)

摘 要

数控加工是指在数控机床上进行零件加工的一种工艺方法,数控机床加工与传统机床加工的工艺规程从总体上说是一致的,但也发生了明显的变化。用数字信息控制零件和刀具位移的机械加工方法。它是解决零件品种多变、批量小、形状复杂、精度高等问题和实现高效化和自动化加工的有效途径。数控编程是数控加工准备阶段的主要内容之一,通常包括分析零件图样,确定加工工艺过程;计算走刀轨迹,得出刀位数据;编写数控加工程序;制作控制介质;校对程序及首件试切。有手工编程和自动编程两种方法。

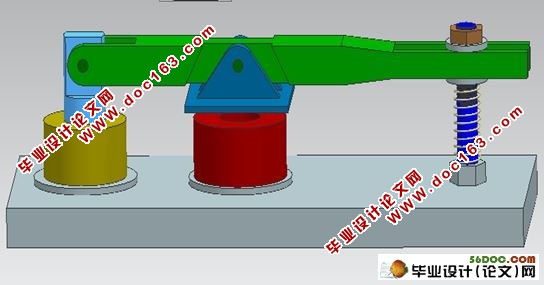

螺旋压板机构是指螺旋副与其他元件相结合,对工件实施夹紧的机构。螺旋夹紧机构在生产中使用极为普遍。螺旋压板机构结构简单,夹紧行程大,且自锁性能好,增力比大,是手动夹紧中采用最多的一种夹紧机构。

本文以塑料壳凹模加工的数控编程为例,对数控编程进行介绍,是零件从图纸到获得数控加工程序的全过程。

本文以螺旋压板机构的设计为例,对夹紧机构进行了介绍。夹具的特点是操作简便,针对性强,夹紧力可靠,结构紧凑,生产效率高,使用安全,且有合理的装卸空间。

[版权所有:http://DOC163.com]

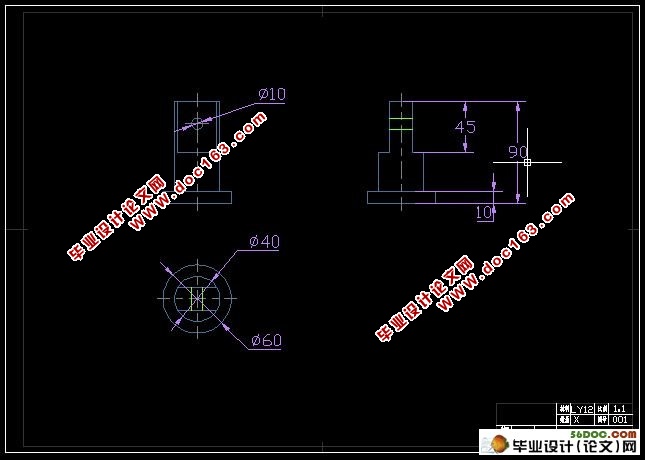

本次设计还运用制图软件UG,AutoCAD对螺旋压板机构的各个零部件进行了三维制图和装配并且绘制了零件图和装配图的工程图。除此之外,还用了UG对塑料壳凹模进行了数控加工编程。

关键词:数控编程,螺旋压板机构,夹紧机构,装配图,工程图

ABSTRACT

CNC machining refers to a process for parts on CNC machine tools for machining, CNC machining process planning with traditional machining said in general is the same, but significant changes have taken place. Digital information control parts and machining tool displacement method. It is to solve the parts changing varieties, small batch, complex shape, high precision problems and achieve efficient and effective way to automated processing. CNC programming CNC machining is one of the main stages of preparation, often including parts pattern analysis to determine the machining process; calculate the trajectory passes, drawn cutter location data; write NC programs; production control medium; proofreading process and the first pieces of test cut. There are manual programming and automatic programming of two ways.

[资料来源:www.doc163.com]

Platen mechanism is the helical screw pair combination with other elements, the clamping mechanism of a workpiece. Screw clamping mechanism is very common to use in production. Spiral plate mechanism is simple structure, large clamping stroke, and good self-locking performance, increase strength ratio, is used in most manual clamping a clamping mechanism.

In this paper, the plastic case of the die machining CNC programming example, introduced CNC programming is drawing to get parts from CNC machining program the entire process.

In this paper, spiral plate design agency, for example, of the clamping mechanism were introduced. Fixture features a simple, targeted, clamping force, reliable, compact, high production efficiency, safety, and there is a reasonable handling space.

The design also uses mapping software UG, AutoCAD various parts of the spiral plate bodies were assembled and three-dimensional mapping and drawn parts and assembly drawings. In addition, also with a plastic shell die UG conducted on NC programming.

[版权所有:http://DOC163.com]

Keywords: CNC programming,spiral plate institutions,clamping mechanism,assembly drawing, engineering drawings

在对螺旋压板机构总体设计之前,需要确定螺旋压板机构的夹紧方式,基本类型以及绘制草图,并根据结构特点和要达到的要求进行分析,如各个部分的尺寸、形状、连接方式等。然后还必须深入了解螺旋压板机构的工作原理,大量收集资料和尺寸数据,了解螺旋压板机构的优缺点,并进行改良和再设计。然后是总体方案的设计,总体方案设计的具体工作是绘制各个组成零件的三维设计图、工程图、装配图并导出CAD图且进行数据标注。本次毕业设计还包含了塑料凹模的速控仿真加工,它是一个将设计转化为实物的过程,通过仿真我们可以完善设计方案,并对零件的可加工性进行检测,同时还是一个系统熟悉UG软件的过程。

通过分析和借鉴图1-1的模型机构,并自己设计出一个螺旋压板机构。

主要技术指标

1、确定自己用UG三维软件技术进行设计的思路和方案。

2、掌握UG、AutoCAD等软件的使用方法。

3、用UG软件设计一个螺旋压板机构。

4、用UG应用软件系统完塑料壳凹模模加工的数控编程。

5、撰写论文,阐述自己毕业设计的工作内容。 [来源:http://Doc163.com]

[资料来源:http://doc163.com]

[资料来源:http://Doc163.com]

目 录

摘要 Ⅰ

ABSTRACT Ⅱ

[资料来源:www.doc163.com]

第1章 绪论 5

1.1数控加工的发展背景 5

1.2国内外的发展史及研究动态 5 [来源:http://Doc163.com]

1.3研究背景 6

1.4选题的意义 6

1.5本次设计的简介 7 [资料来源:https://www.doc163.com]

第2章 螺旋压板机构的简介 8

2.1螺旋压板机构的初步认识 8

2.2夹具的分类 9 [资料来源:http://doc163.com]

2.2.1万能通用夹具 9

2.2.2 专用性夹具 9

2.2.3可调夹具 9

2.2.4组合夹具 9

2.2.5组成夹具 9

2.2.6 自动线夹具 9

[资料来源:https://www.doc163.com]

2.3螺旋压板机构的特点 10

2.4 本章小结 10

第3章 设计过程中软件的功能介绍 11

3.1 UG软件的简介 11

3.2 UG软件的操作解析 11

3.2.1 UG界面介绍 11

[来源:http://Doc163.com]

3.2.2鼠标功能 13

3.2.3 工具条 13

3.3 Auto CAD软件的简介 13 [资料来源:www.doc163.com]

3.3.1 Auto CAD的发展史 13

3.3.2 Auto CAD的工作界面 13

3.4本章小结 14

第4章 塑料壳凹模的数控编程 15 [资料来源:www.doc163.com]

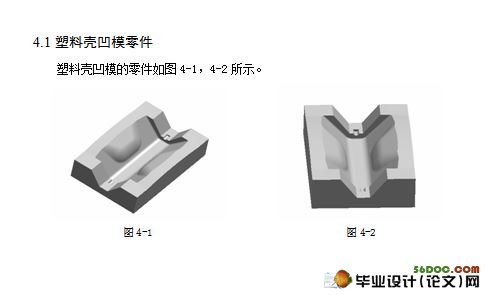

4.1塑料壳凹模零件 15

4.2 塑料壳凹模加工的工艺路线 15

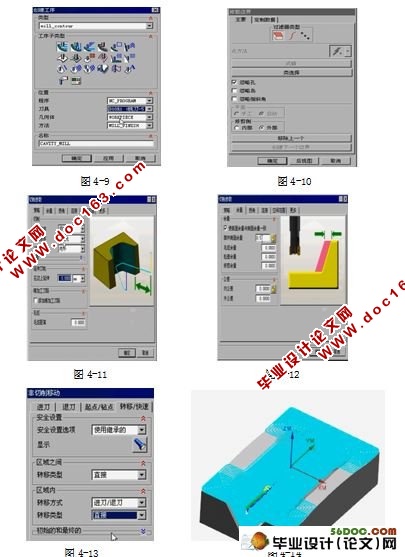

4.3 塑料壳凹模的数控加工 15 [资料来源:Doc163.com]

4.4 本章小结 23

第5章 零件建模 24

5.1 制图过程 24 [资料来源:http://doc163.com]

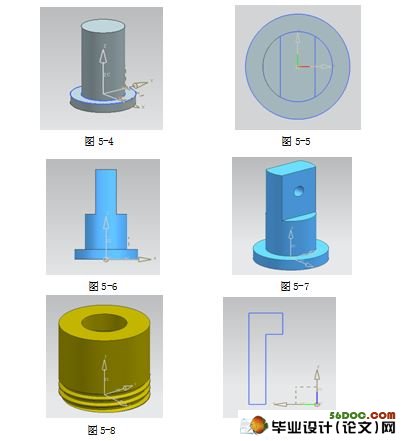

5.2 零件建模过程 24

5.3 本章小结 33

第6章 工程图的绘制 34 [来源:http://Doc163.com]

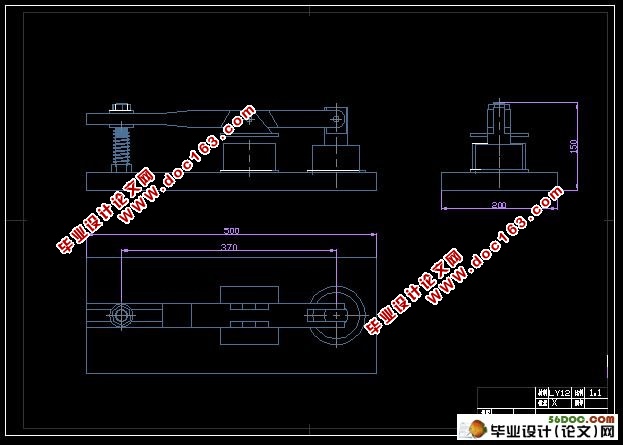

6.1 主要零件工程图的绘制 34

6.2 整体装配图的绘制 37

6.3 本章小结 37

第7章 螺旋压板机构的装配 38

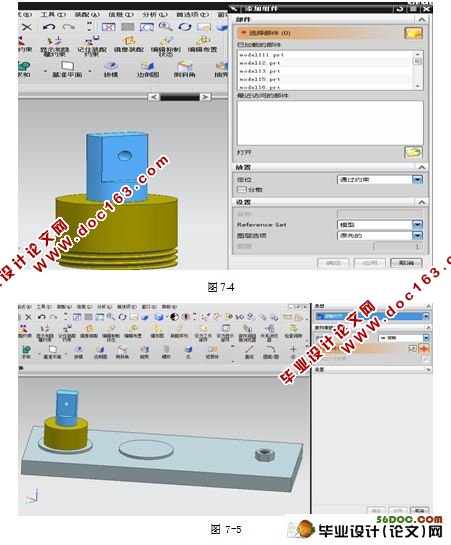

7.1 装配操作的基本步骤 38

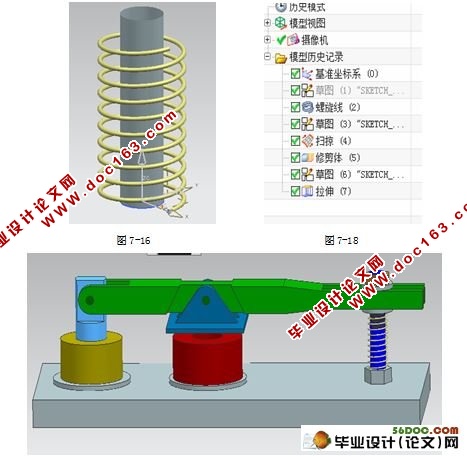

7.2 螺旋压板机构的装配过程 38

7.3 本章小结 43 [资料来源:Doc163.com]

第8章 全文总结 44

第9章 毕业设计心得体会 45

参考文献 47

[资料来源:Doc163.com]

致谢 48

附录 49 [资料来源:http://www.doc163.com]

上一篇:螺纹轴车削加工及数控车削机床仿真的研究(CAD,CATIA,NC加工程序)

下一篇:主板反馈后框工艺编制及实体加工仿真(CAD零件图,工艺卡)