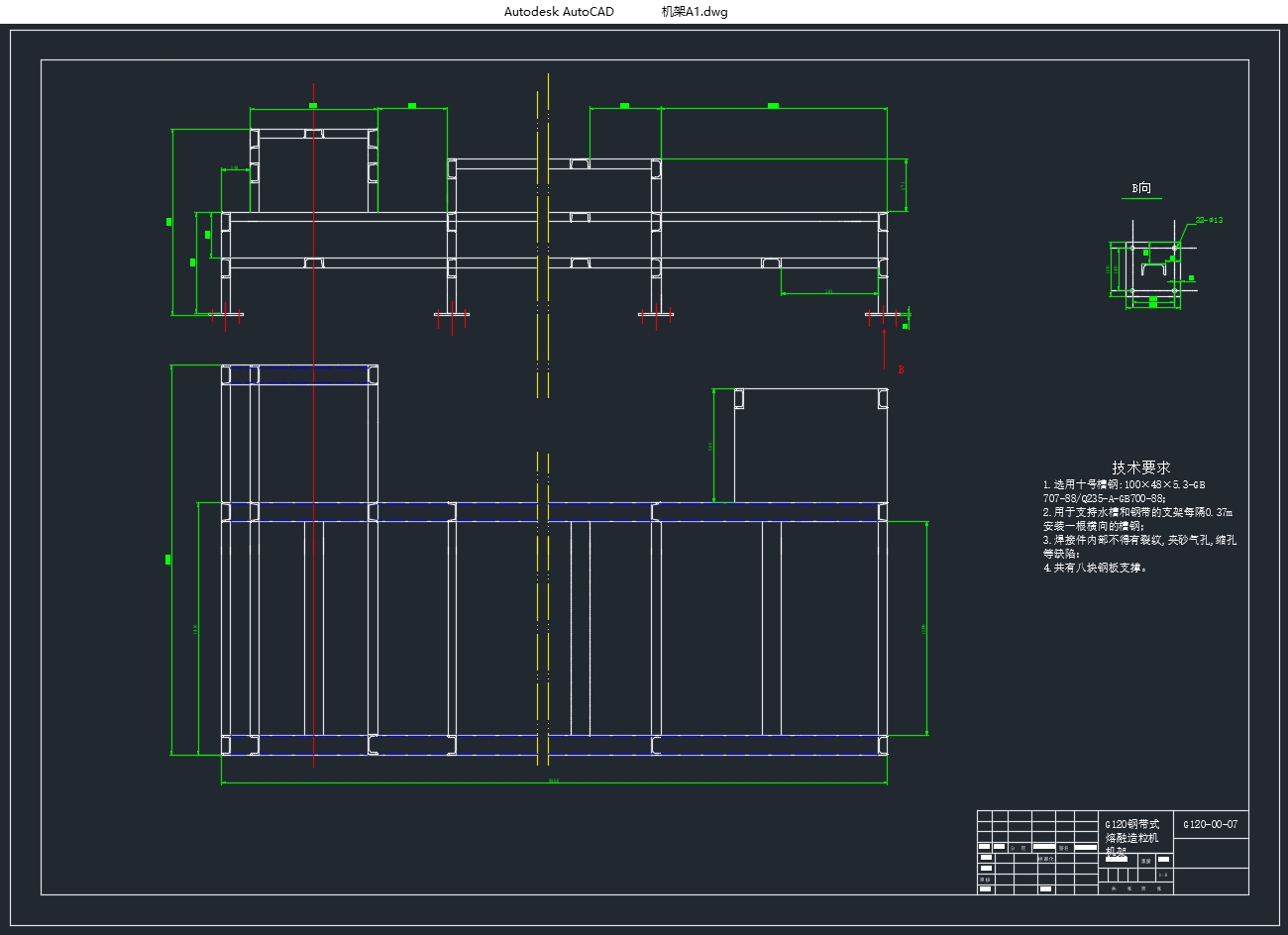

G120型钢带式熔融造粒机设计(含CAD零件图装配图)

G120型钢带式熔融造粒机设计(含CAD零件图装配图)(任务书,开题报告,外文翻译,论文说明书10400字,CAD图纸10张)

摘要

众所周知,低熔点物料(通常指熔点在40-300℃之间的物料)在熔融状态下具有可流动性,在常温下呈固态形式。在熔点以上,物料的粘度、表面张力随温度的变化而变化。当我们将熔融液间断地滴落在平板上,由于液体的表面张力的作用,液滴在板上呈半球状,经冷却后得到半球状的固体颗粒。日本《造粒便览》将该物理过程称之为“板上滴下自然落模成型造粒法”。根据这一原理,我们可以设计钢带式熔融造粒技术及其装置。

该造粒机主要由以下几部分组成:①布料器;②钢带输送系统;③喷淋冷却系统;④操作控制系统(温度、速度控制)。其工作原理为:熔融物料连续进入被恒温控制的布料器内,并由该装置将熔融料经压力均布后沿钢带宽度范围向下转化为断续滴落的液滴,同时滴落在其下方匀速移动的钢带上。在钢带下设有喷淋冷却装置,使滴落在钢带上面的物料经薄钢带传热并在移动、输送的过程中得到强制冷却固化。从而形成规则的半球状颗粒产品。根据成型和物性的需要,布料器可选择断续滴落、连续出条和全宽度溢流的形式,从而可分别得到半球状、条状和不规则片状产品。

[资料来源:http://www.doc163.com]

关键词:造粒机 钢带 喷淋冷却

Design of G120 Steel-Band type Melting Granulator

Abstract

As is known, low-melting materials (usually themelting point among 40-300℃) show well liquidity under the molten state, whereas are solid state under the normal atmospheric temperature.Above the melting point, viscidity and surface tension of the materials vary with temperature. As the melting liquid drops to the flat platedisconnectedly, the drops because of the liquid surface tension are semicircular in shape on the board, and then get hemispherical solid particles after cooling. The book《Brief Guide of Granulate》namedthis process “ granular molding methodby falling naturally upon the board”. According to this principle, we design the technology and devices about the steel-band type melting granulator.

This granulator is made up of several following parts mainly:①Distributing device;②Steel-Band transfer system;③Spray cooling system;④Operationcontrol system (controltemperature andtransfer speed). The operating principle is: melting materialsare feed continuously into thedistributing device under thermostatic control , and are pressedand converted into liquid drops. Then the melting materials drop down to the steel-band which moves at uniform velocity.Spray cooling device are assembled under the steel-band to make the melting materials dropping upon the steel-band transfer heat and forced cool them during the process of moving and deliveringby the thin steel-band, then regular hemispherical particle products would be obtained. According to the requirements of shaping and physical appearance, we can choose various distributing devices such as drop discontinuously,continuouslyorfull duration overflowing form so that to prepare hemispherical, banding or irregular flaky products.

Keyword: granulator steel-band Spray cooling system

2.1物料泵的选取

作用:用于输送熔融液

硫磺的密度ρ=2.0×103 Kg/m3

造粒机的造粒能力C=1000Kg/h

每小时的硫磺的流量Q=C/ρ=1000/2000=0.5 m3/h

所以可选择型32-20-160 SES化工离心泵

目录

摘 要 Ⅰ [资料来源:http://doc163.com]

Abstract Ⅱ

第一章 概述 1

1.1 概述 1

1.2 钢带式熔融造粒技术介绍 2

1.2.1 工作原理 2

1.2.2 性能特点 4

1.2.3 工艺配置 5

1.2.4 与其它处理方式的比较 5

1.3影响造粒成型质量的几个主要因素 6

1.4硫磺造粒工艺及其应用 7

第二章 钢带式熔融造粒机的计算 8

2.1物料泵的选取 8

2.2物料罐尺寸的选取 9

2.3保温材料的选择 9

2.4单位颗粒产品质量M 9

2.5颗粒冷却固化时间 9

2.6钢带的设计 10

2.6.1冷却钢带有效宽度 10

2.6.2颗粒冷却固化时间t 10

2.6.3钢带冷却区长度L(m) 10

2.7滚筒轴的设计 11

2.7.1主动轮轴的设计 11 [来源:http://www.doc163.com]

2.7.2从动轮轴的设计 14

2.8滚筒的传动装置 14

2.8.1电动机的选择 14

2.8.2减速器的选择 14

2.8.3带轮的选取 15

2.9冷却水量W(m3/h) 17

2.10给水泵的选取 18

2.11布料器的计算 19

2.11.1转鼓横截面积 19

2.11.2布料器的转速 19

2.11.3布料器的宽度 19

2.11.4布料器内的物料重 19

2.11.5布料器内的传动装置 20

2.12刮料装置 22

2.12.1刮刀装置 22

2.12.2 刮刀设计 23

2.12.3 刮刀架、支承轴和压力调节器设计 23

2.13下料口的设计 24

结 语 25

参考文献 26

致 谢 27

[来源:http://Doc163.com]

下一篇:MQ4033门座起重机总体及臂架系统设计(含CAD图,SolidWorks三维图)