热压罐模具对复合材料构件固化变形的影响分析

热压罐模具对复合材料构件固化变形的影响分析(任务书,开题报告,论文14000字)

摘 要

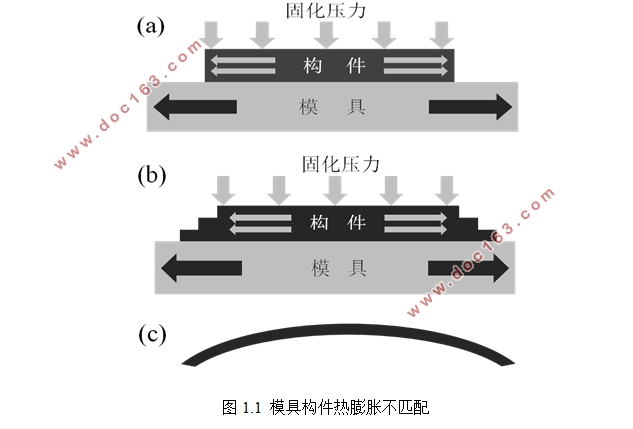

影响复合材料固化变形的因素有很多,既有材料内部因素如材料性质、铺层方式等,也有外部环境因素如模具、温度、固化制度等。模具因素是影响复合材料固化变形很重要的外部因素,模具对复合材料构件固化变形影响途径包括:模具与构件间热变形不匹配所致的相互作用以及高热容量模具引起的材料内部温度不均匀。

文章探究热压罐成型过程中铝质模具的不同表面处理方式对复合材料翘曲变形的影响,包括脱模剂,隔离膜、脱模布等不同处理方式,测量了构件固化成型后的翘曲量。通过测量模具与构件间类摩擦力大小对模具表面质量与试样间的相互作用进行了分析,结果表明采用隔离膜和脱模布可显著降低平面内的模具作用力。

其次本文采用光纤布拉格光栅(FBG)监测了高热容量模具表面复合材料平板在热压罐成型过程中不同厚度方向的温度分布情况与凝胶过程。捕捉了层合板内部温度梯度分布与其固化不同步现象,证明了模具热容对材料固化过程的影响,为进一步研究固化残余应力分布提供了技术支撑。

关键词:复合材料;固化变形;热压罐成型;模具;光纤布拉格光栅

Abstract

[资料来源:http://doc163.com]

There are many factors affecting the composite curing deformation. Both internal factors such as the material properties of the material, overlay mode, but also external environmental factors such as mold, temperature, curing system.Mold is a very important factor of external factors affecting the composite curing deformation.There are two reasons for curing composite deformation: tool-part interaction due to thermal expansion mismatch and an uneven temperature distribution within the material caused by high heat capacity of the mold.

Explored the effects of different surface treatments of mold on the composite warpage in autoclave molding process. Mold surface with different treatments include release agent, stick isolation membrane, demoulding cloth, etc.Component of warping is measured after curing. In addition, analyzed the interaction between the mold surface and the sample by measuring tool-part friction.The results showed that the use of the insulating film and a release cloth can significantly reduce the mold plane force.

[资料来源:Doc163.com]

Monitored the different thickness of composite laminated plate on the surface of the mold with high heat capacity along the direction of the temperature distribution and gel process in autoclave molding process by fiber Bragg grating (FBG).And captured the laminate internal temperature gradient distribution of its curing is not synchronous, confirmed the influence of the mold with high heat capacity on material curing process and provided technical support to further study the curing residual stress distribution.

Keywords: Composite, Curing deformation, Autoclave molding, Mold, Fiber Bragg grating

目 录

摘要 I

Abstract II

第1章 绪论 1

1.1 复合材料的应用进展 1

1.2复合材料的固化变形问题及基本成因讨论 1

1.3热压罐模具对复合材料变形的影响研究 4

1.4本文研究内容 7

第2章 模具表面对固化变形的影响 8

2.1 热压罐固化成型工艺 8

2.2 不同表面处理方式对复合材料固化变形的影响 9

2.3 模具表面情况对模具与构件间接触力的影响 11

第3章 基于FBG的厚板固化过程监测 15

3.1 基于FBG的厚板固化监测实验 15

3.2 不同厚度处的温度分布情况 17

[资料来源:http://Doc163.com]

3.3不同厚度处的凝胶过程分析 17

第4章 结论与展望 24

参考文献 25

致谢 27 [来源:http://Doc163.com]