DFB半导体激光器驱动电路的研制

DFB半导体激光器驱动电路的研制(任务书,开题报告,外文翻译,论文12000字)

摘要

近些年来以来,我国发展面临着很多问题,比如空气污染越来越严重,尤其是华北地区以及东北地区空气污染十分严重,已经使人们面临着健康问题,实时监测空气成分成为必须的一项工作。而且,随着我国经济的发展,需要越来越多的矿产资源的支持,矿产工程又充满了不可测性和危险性,因此必须有一定的稳定设备来检测矿洞中的空气成分,因此我们需要能够稳定监测气体的工具。我国在这方面的研究起步较国外晚。国外对于激光器驱动电路的研究比较早,并且获得了很大的突破,技术方面相对比较成熟了,尤其是日本,美国均有一些技术突破,其中有一些公司例如美国的ILXLightwave Thorlabs以及韩国的M-Teeh等这些公司都掌握了一定的技术水平,这些公司研制出的激光器驱动电路也得到了广泛应用和认可,其技术指标十分优秀,脉冲宽度可以达到皮秒级,电流大小也能达到上百安培。而我国的研究起步就比较晚,在这方面有一些落后,因此研制更加精良,技术标准更高的激光驱动电路势在必行。

因为我们要驱动的是半导体激光器,其对电压和电流都十分敏感,操作不当,或者驱动电路输出不稳定都会造成激光器的损害和失效,存在很大的安全隐患。我此次设计的半导体驱动电路的思路是先通过仿真软件将电路图设计模拟出来,然后仿真运行,当仿真成功后,将系统模块化,将整个电路图分成几个模块,分别对几个模块进行分析和调试,以达到更高的精准度。然后购买硬件组建,将硬件根据电路图焊接调试成功,最后将几个模块组装并进行整体的调试,完成本次驱动电路的设计。 [资料来源:https://www.doc163.com]

目前我的设计工作已经全面完成,硬件已经焊接调试好,并且可以达到较高的标准。在实际应用过程中,此驱动电路可以驱动半导体激光器发出激光脉冲,并且发出的激光脉冲十分稳定,接近于商用半导体激光器发出的激光标准,我的设计驱动发出的激光脉冲的长度分别是1530.1400 1548.4760 1566.9480。并且可以保证长时间稳定运行。此次电路设计已经基本完成,并且可以实现相应功能。

关键词:半导体激光器 驱动电路 敏感 模块化 激光脉冲

Abstract

In recent years, China's development is facing many problems, such as air pollution is more and more serious, especially in North China and northeast air pollution is very serious, is that people are faced with health problems, real-time monitoring of air composition has become a necessary. Moreover, with the development of China's economy, we need more and more support of mineral resources, mineral engineering and full of uncertainty and risk, so there must be a stable equipment to detect air components of mines, so we need to be able to work out the stability monitoring of gas. Our research in this field started later than abroad. Study abroad in the laser driving circuit is relatively early, and gained a great breakthrough, the technology is relatively mature, especially in Japan, the United States has some technological breakthroughs, some companies such as the United States and South Korea's M-Teeh ILXLightwave Thorlabs, these companies have mastered a certain level of technology, the company developed a laser the driving circuit has been widely used and recognized, its technical performance is very good, the pulse width can reach picosecond, current size can reach hundreds of amperes. But the research in our country started relatively late, and there are some backward in this aspect. Therefore, it is imperative to develop more sophisticated laser drive circuit with higher technical standards. [来源:http://Doc163.com]

Because we want to drive the semiconductor laser, which are very sensitive to voltage and current output driver circuit or improper operation, will cause the instability of laser damage and failure, there is a big security risk. The design of the driving circuit of semiconductor my idea is first through the simulation software for circuit design and simulation, simulation, when the simulation is successful, the system is modular, the whole circuit is divided into several modules, respectively, of several modules analysis and debugging, to achieve higher accuracy. Then buy the hardware to build, the hardware according to the circuit diagram welding debugging success, and finally will be a few modules assembled and the whole debugging, completed the drive circuit design.

At present, my design work has been fully completed, the hardware has been welding debugging, and can achieve higher standards. In the actual application process, this circuit can drive semiconductor laser pulse, laser pulse and a very stable, close to the standard commercial laser emitted by the semiconductor laser, I design a driving laser pulse length is 1530.1400 1548.4760 1566.9480 respectively. And it can ensure stable operation for a long time. The circuit design has been basically completed, and can achieve the corresponding function.

[资料来源:www.doc163.com]

Key words: semiconductor laser; drive circuit; sensitive modular laser pulse

[来源:http://www.doc163.com]

目录

第1章绪论 1

1.1课题的背景及意义 1

1.2国内外相关技术及研究现状 2

1.2.1国外研究现状 2

1.2.2 国内研究现状 2

1.3论文研究主要内容 3

第2章 方案论证与设计 4

2.1需求分析 4

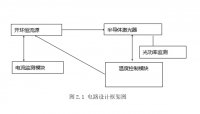

2.2系统总体分析 4

2.3系统设计原理分析 5

2.3.1 DFB激光器的原理 5

2.3.2 MOS管功率放大器 6 [资料来源:http://www.doc163.com]

2.3.3 恒流源LM385介绍 7

2.3.4 运算放大器TLC2272 7

2.3.5 PNP管介绍 9

2.3.6温度控制芯片ADN8831介绍 10

第3章 电路整体设计方案 13

3.1电路整体设计图 13

3.2各模块作用 14

3.2.1开环恒流源 14

3.2.2电流监测模块 15

3.2.3光电监测模块 15

3.2.4激光器电路 16

3.2.5温度控制芯片模块 17

3.3 电路工作原理 18

第4章 系统调试及结果 19

4.1电路调试以及数据测量 19

4.2设计结果分析 21

第5章 总结和展望 22

参考文献 23

致谢 24 [资料来源:https://www.doc163.com]